Welcome to the HealthPlast pharmaceutical packaging blog. Here we share insights on PVC, PVDC, PET films, and aluminum foils used in pharma blister packaging. Stay updated on trends, materials, and innovations from a trusted pharmaceutical packaging film manufacturer.

Pharmaceutical Packaging Blog & Industry Updates

Is PVC Film Still the Invisible Shield of Pharma Packaging?

Medicines are afraid of moisture, light and breakage, and the consequences of choosing the wrong packaging can be serious.

Yes, PVC film continues to be one of the most reliable solutions in pharmaceutical packaging. It offers excellent transparency, moisture resistance, and compatibility with aluminium foil, making it ideal for maintaining the shelf life and integrity of tablets and capsules.

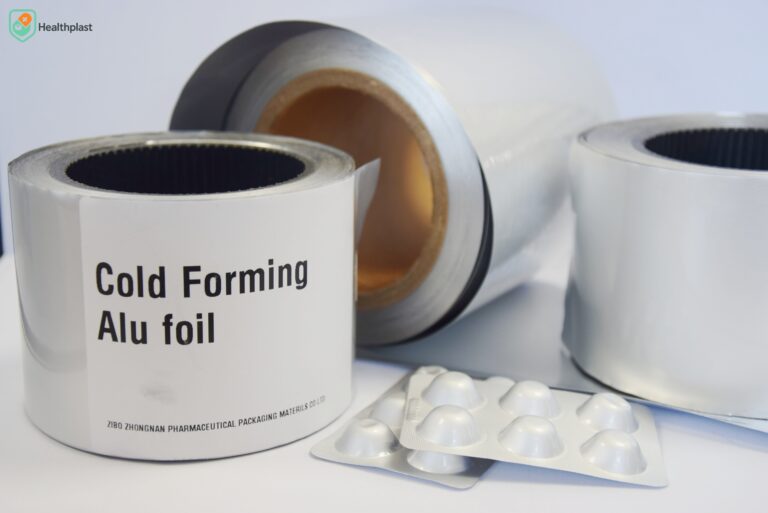

In one pharmaceutical workshop, rolls of PVC film run rhythmically on the production line. Lao Wang, the workshop director, points to the sealing station and says, “This thin film is the first line of defence.” With its clarity, flexibility, and heat-sealing compatibility, PVC forms an unbeatable combo with aluminium foil — keeping out both moisture and light.

While newer materials are emerging, from PET to EVOH, PVC still holds the line in terms of process maturity and cost efficiency. But as environmental concerns and material innovation accelerate, is it time to rethink the future of pharma packaging?

Of course, no material is perfect. PVC film, while reliable, is not immune to challenges. In one southern pharmaceutical plant, engineers noticed a decline in seal quality during the rainy season. “The PVC felt soft and didn’t seal well,” a technician recalled. By adjusting temperature and humidity in the workshop, the issue was resolved — a reminder that even trusted materials demand precise handling.

Alternative films like PET, PVDC, and EVOH are gaining attention. They promise better barrier performance or eco-friendliness, but they also come with higher costs and processing challenges. For many pharma companies, PVC remains the ‘workhorse’ — cost-effective, widely available, and compatible with existing production lines.

In today’s fast-moving world, packaging often gets overlooked. But when you unwrap a tablet and see that clear protective layer, remember: it’s more than just plastic — it’s years of material science at work, silently guarding what matters most.

Still wondering if PVC is right for your pharma packaging? Let’s talk.

Written by Nancy Zhou, a packaging sales specialist with 12 years of experience in the plastics industry. She helps pharma companies across Asia find practical, effective packaging solutions tailored to their unique environments.