PVC/PVDC Film for Pharma Blister Packaging

Product Overview

HealthPlast PVC/PVDC Film for Pharma Blister Packaging is a high-performance, dual-layer film specially designed for solid oral dosage forms requiring enhanced moisture and oxygen protection. By coating standard rigid pharmaceutical PVC with a precision-applied polyvinylidene chloride (PVDC) layer, it offers a balanced solution between barrier performance, cost-efficiency, and thermoformability.

PVC/PVDC film is widely used in global blister packaging lines where environmental humidity presents a challenge, and product shelf life is critical.

Technical Specifications

| Property | Specification | Test Method |

| Total Thickness | 250μm – 350μm | ISO 4593 |

| PVDC Coating Weight | 40–120gsm (single or double side) | Internal Spec |

| Water Vapor Transmission Rate | ≤0.25 g/m²·24h (38°C, 90%RH) | ASTM E96 |

| Oxygen Transmission Rate | ≤1.0 cc/m²·24h (23°C, 0%RH) | ASTM D3985 |

| Formability | Excellent (up to 8mm cavity depth) | Internal Test |

| Bond Strength (PVC to PVDC) | ≥5.0 N/15mm | ASTM D1876 |

PVC/PVDC film Applications:

Moisture-Sensitive Tablets & Capsules

Vitamins, probiotics, antibiotics

Light-Sensitive Formulations

Available in amber-colored PVC base

Tropical Zone Markets

Suitable for Southeast Asia, Latin America, Africa

Standard Blister Packaging Lines

Compatible with PVC-forming molds

Widely used in packing of pharm grade solid oral preparations & food,excellent moistureproof property,5-10 times barrier performance compared with PVC.

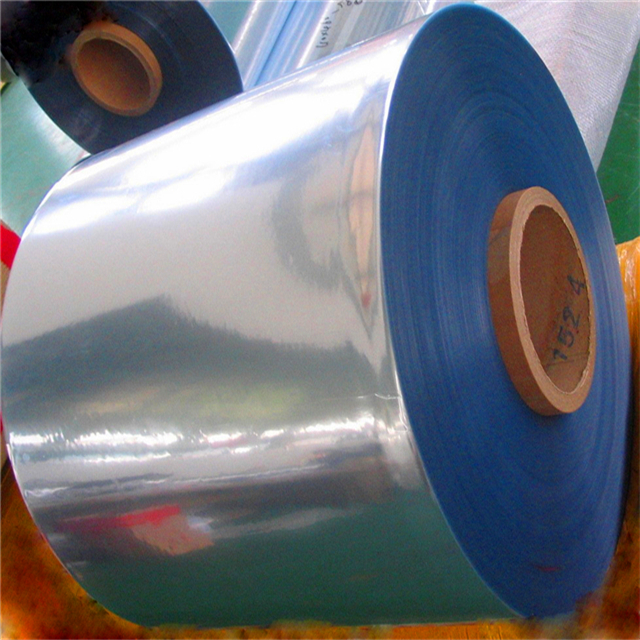

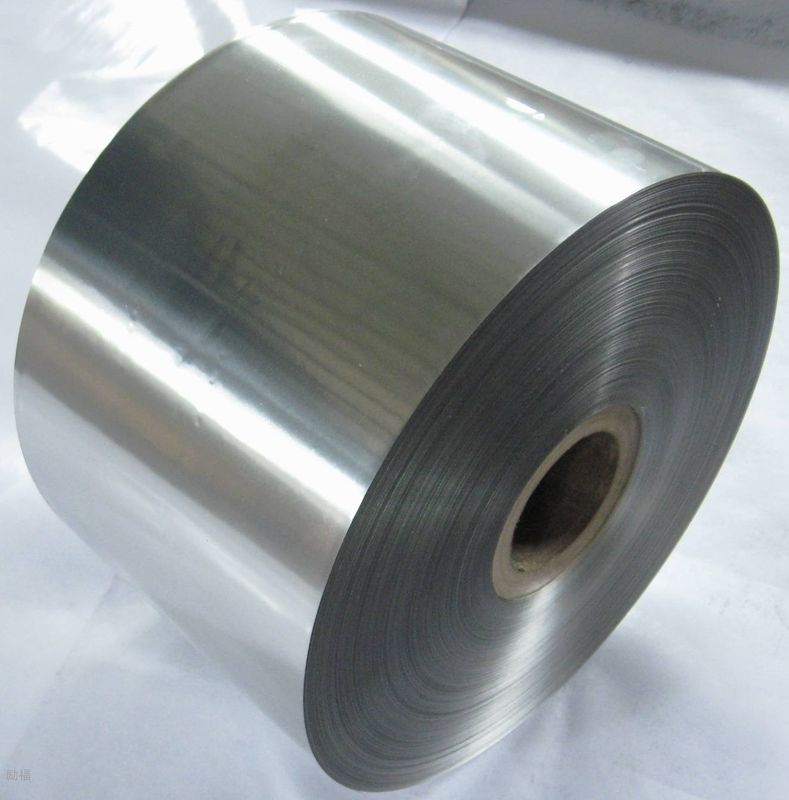

PVC/PVDC FILM Supply & Delivery

Width Range: 250mm to 980mm

Core Size: 73mm plastic core

Roll Length: Customizable up to 5000m

Color Options: Clear / Light yellow / Amber/Red

Shelf Life: 12 months under 25℃ & <60% RH

FAQs – PVC/PVDC Film

Q1: What is the difference between single-side and double-side PVDC coating?

A: Single-side coating is standard for blister forming. Double-side is for duplex barrier where lidding foil is omitted or moisture exposure from both sides exists.

Q2: Is the PVDC FDA and EU compliant?

A: Yes. We use food/pharma-grade PVDC resin compliant with FDA 21 CFR 177.1630 and EU Regulation No. 10/2011.

Q3: How does it compare to Alu-Alu foil?

A: While not matching Alu-Alu’s barrier strength, PVC/PVDC is more cost-effective and easier to thermoform, with lower environmental footprint.

Q4: Can it be used with tropical blister foil?

A: Yes. Many clients combine PVC/PVDC as forming film with Tropical Aluminum Foil as lidding layer for extreme humidity protection.

Why Choose HealthPlast PVC/PVDC Film?

In-house PVDC precision coating line (cleanroom grade)

100% pharma-grade, batch-traceable raw materials

Wide range of coating weights (40–120 gsm) available

Proven supply to over 60 countries across humid climates

Custom roll formats, colors, and pre-cut services