Alu-AluFoil – Ultimate Protection for Moisture & Light-Sensitive Medicines

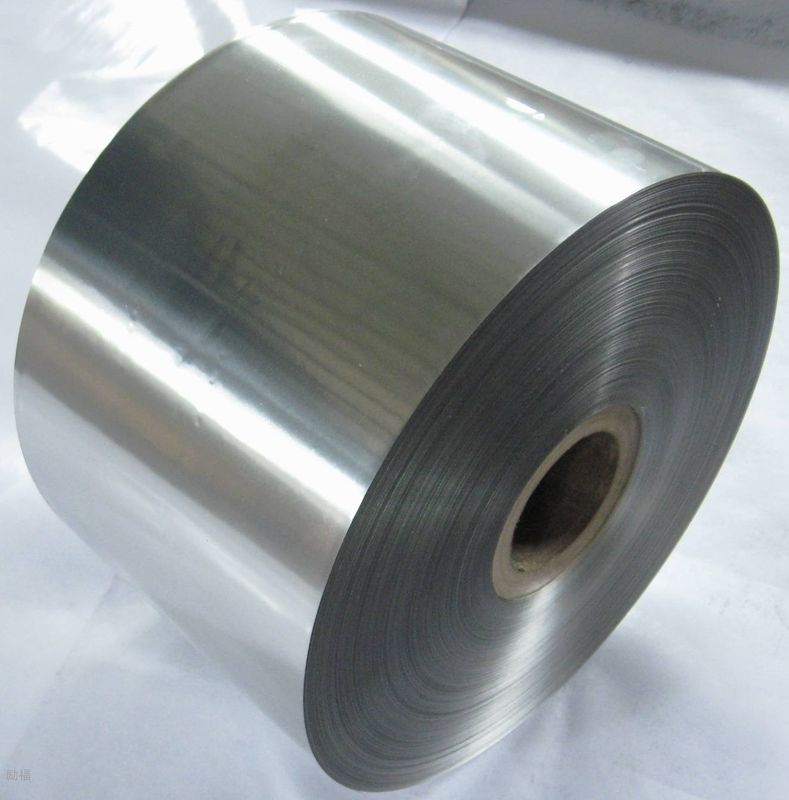

HealthPlast Alu-Alu Foil (also known as Cold-Formed Blister Foil) is engineered for the highest barrier performance in pharmaceutical packaging. Designed to protect sensitive drugs from moisture, oxygen, light, and contamination,

This three-layer laminate (OPA/ALU/PVC) is designed to protect sensitive medicines from moisture, oxygen, light, and contamination. It helps extend shelf life and meets global pharmaceutical regulations.

Construction

| Layer | Material | Function |

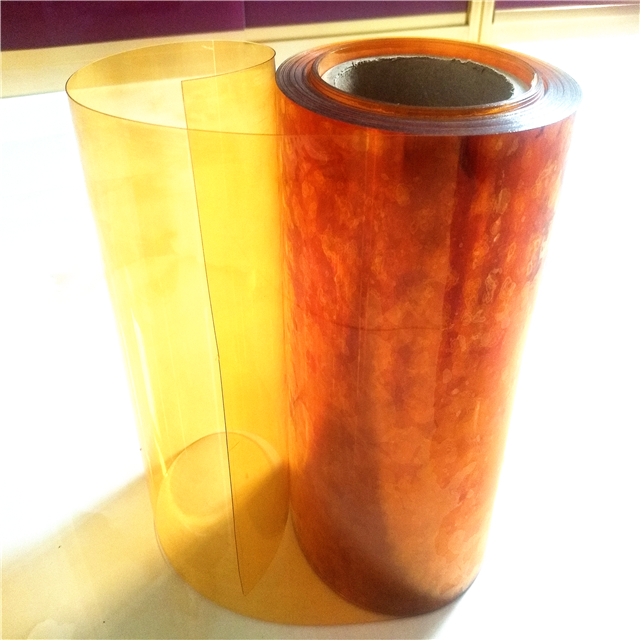

| Outer Layer | Oriented Polyamide (OPA) | Mechanical strength & forming support |

| Core Layer | Aluminum Foil | Absolute barrier to moisture, gas, and light |

| Inner Layer | PVC / PP | Heat sealability with lidding foil (typically printed aluminum) |

Available with PVC or PP inner layer based on your forming and sealing requirements.

Technical Specifications

| Property | Specification | Test Standard |

| Total Thickness | 150μm – 200μm | ASTM F2251 |

| WVTR (38°C, 90% RH) | ≤ 0.002 g/m²·24h | ASTM F1249 |

| OTR (23°C, 0% RH) | ≤ 0.005 cc/m²·24h | ASTM D3985 |

| Formability (depth) | Up to 12 mm without cracking | In-house validated |

| Heat Seal Strength | ≥ 7 N/15mm (with standard Alu lidding) | ASTM F88 |

| Compatibility | PVC-based or PP-based sealing films | ISO 11607 / EN 868 |

| Heat Seal Strength | ≥ 7 N/15mm (with standard Alu lidding) | ASTM F88 |

| Compatibility | PVC-based or PP-based sealing films | ISO 11607 / EN 868 |

Alu-Alu foil Core Applications

Moisture-sensitive drugs: antibiotics, probiotics, effervescent tablets

Light-sensitive products: vitamins, antihistamines, enzyme tablets

Long-shelf-life drugs: MENA & tropical climates with high humidity

Combination products: multi-tablet regimens requiring deep pockets

Key Advantages

100% barrier against moisture, oxygen, and light

Excellent Alu-alu foil depth for customized blister shapes

Compatible with high-speed blister packaging machines

Optional textured surface for anti-glare & premium look

Available in Alu-alu foil or pre-printed version

Supply Details

Width: 200mm – 980mm (customizable)

Core: 76mm (3-inch) plastic or paper core

Packaging: Aluminum bag + carton + export pallet

MOQ: 500 kg / type

Lead time: 12–15 working days

FAQ – Alu-Alu Foil

Q1: Can this foil be printed?

Yes, we offer 6–8 color rotogravure printing with medical-grade inks (EU 10/2011 compliant). Printing is on the lidding foil side, not forming foil.

Q2: Is it suitable for tropical zone storage?

Absolutely. Our Alu-Alu foil is engineered for high-humidity environments, with certified barrier properties proven in accelerated aging tests (40°C/75% RH).

Q3: Can you match forming machine specs?

Yes, just provide your forming machine model (Uhlmann, IMA, Romaco, etc.), and we can pre-trim rolls or adjust foil stiffness accordingly.

Q4: What are the regulatory certificates?

ISO 9001, CE, DMF Type III (upon request), USP <661>, and global regulatory support available