Colored PVC Film for Pharmaceutical & Nutraceutical Packaging

HealthPlast Colored PVC Film are specially engineered to combine visual differentiation with protective functionality for pharmaceutical, nutraceutical, and diagnostic packaging. Available in a wide color palette including amber, green, blue, pink, white opaque, these films help reduce UV degradation, enhance consumer recognition, and support branding goals—without compromising barrier performance or machinability.

Colored PVC Film Unique Features

Color-coded safety for pediatric, veterinary, or OTC medications

UV resistance (up to 99%) to protect light-sensitive ingredients

Consistent color density with low ΔE for batch-to-batch uniformity

Cleanroom extrusion with FDA & EU-compliant masterbatches

Compatible with Alu/PVC and PVDC composite structures

Typical Technical Data

| Property | Value | Standard |

| Thickness Range | 150 – 750 microns (±5%) | ISO 4593 |

| Color Tolerance (ΔE) | ≤ 2.0 | CIELAB Scale |

| Light Transmission (Amber Film) | ≤ 1% at 400–500nm | In-house Test |

| WVTR | ≤ 0.5 g/m²·24h @ 38°C, 90% RH | ASTM E96 |

| Tensile Strength (MD / TD) | ≥ 42 MPa / ≥ 38 MPa | ISO 527-3 |

Additional testing available upon request (USP <661.1>, RoHS, etc.)

Colored PVC Film Applications:

Vitamin & Herbal Supplement Blisters

Pediatric & Geriatric Drug Packs

OTC & Retail Pharmacy Brands

Diagnostic Test Strip & Kit Barriers

Veterinary Drug Packaging

Customization & Supply

Colors Available: Amber, white opaque, green, blue, pink, red and custom Pantone

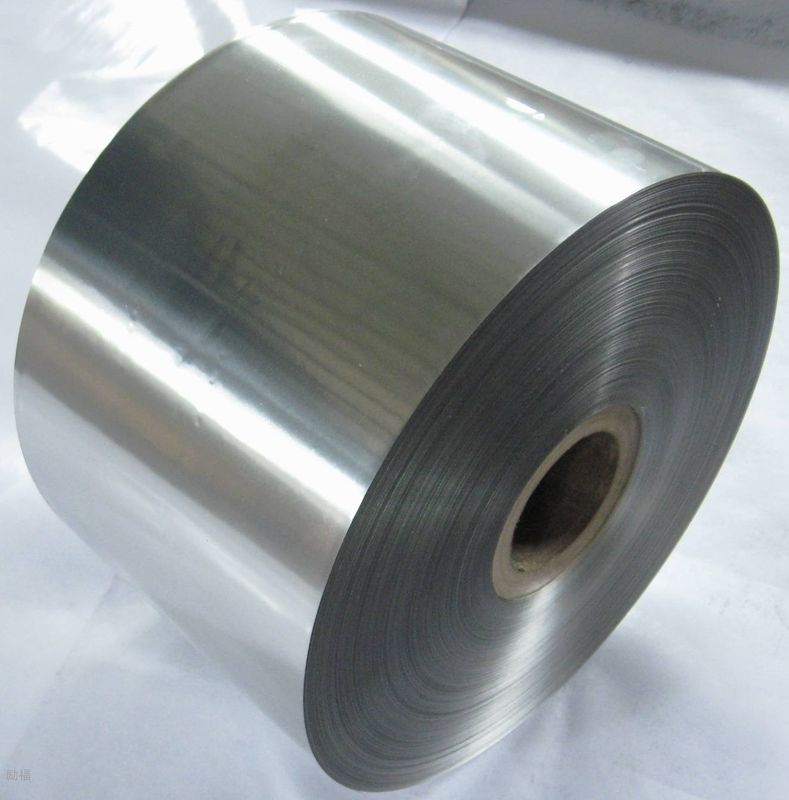

Roll Widths: 80mm to 1100mm (custom slitting supported)

Roll Cores: 76mm core

MOQ: 1 ton (custom color MOQ: 2 tons)

Lead Time: 12–18 working days with color matching approval

Common Client Questions (FAQ)

Q1: Are your colored PVC films compliant with global pharma standards?

Yes. We use pigments that meet FDA 21 CFR, EU EC 10/2011, and USP <661> compatibility.

Q2: Can you match our brand’s color?

Absolutely. Provide Pantone or sample chips—we’ll produce a lab sample for approval.

Q3: Will color affect formability or sealing?

No. Forming and sealing performance are identical to clear PVC films.

Q4: Do you offer dual-function films (e.g. colored + PVDC)?

Yes. We supply colored PVC laminated with PVDC or aluminum foil for tropical climates.

Q5: Is the pigment safe for food or medical contact?

Yes. All colorants are certified non-migratory and comply with pharma-grade material standards.

Why HealthPlast?

Specialist in branded and regulatory-safe colored films since 2006

Trusted by global vitamin, OTC, and medical device companies

Full traceability with COA, MSDS, and batch color records

Small-lot customization & free pre-print layout support

Exported to 60+ countries, with multilingual technical team