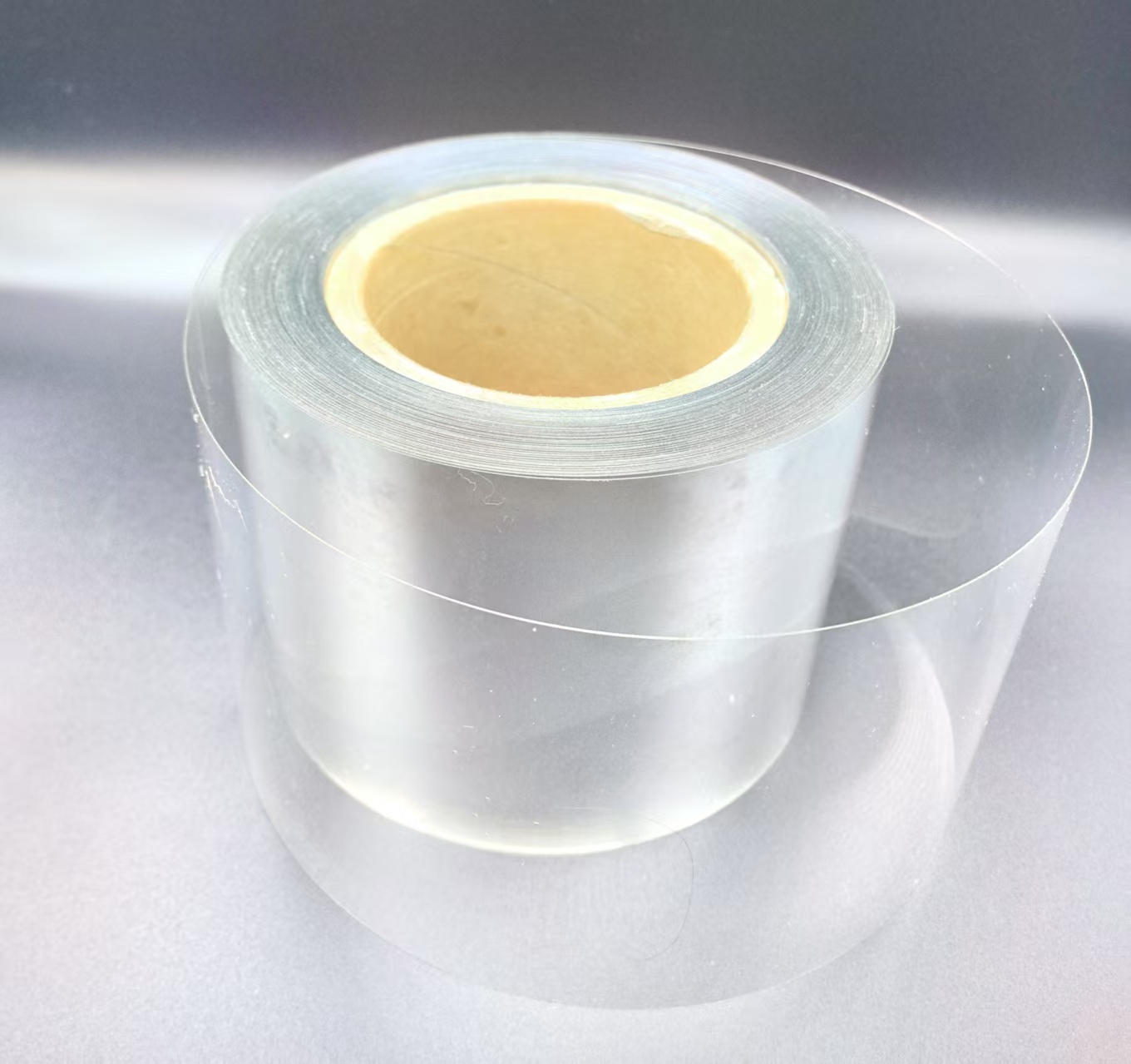

Pharmaceutical PET Film for Medical and Blister Packaging

Product Overview

HealthPlast Pharmaceutical PET Film is a non-PVC, medical-grade polyester film designed for high-performance packaging applications where clarity, chemical resistance, and mechanical strength are critical. It is ideal for non-toxic, eco-conscious, and recyclable pharmaceutical packaging formats.

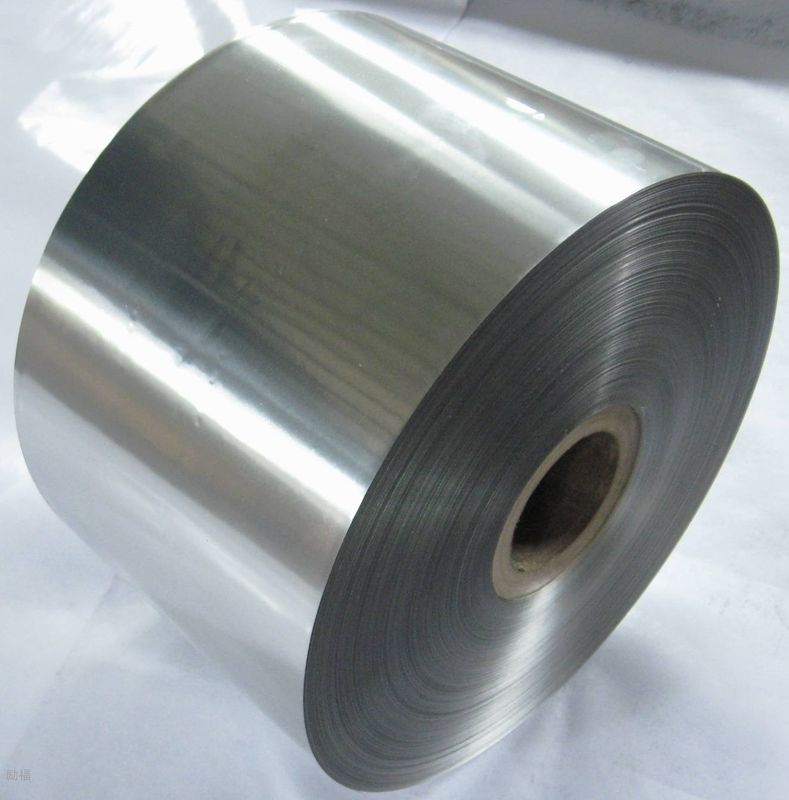

Our PET film serves as a reliable base for lamination with PVDC, PE, or Aluminum Foil, enabling it to meet strict moisture barrier and sealing requirements in blister packs, medical pouches, and diagnostic kits.

Technical Specifications

| Property | Specification | Test Method |

| Thickness | 0.12mm – 0.25mm | ISO 4593 |

| Tensile Strength (MD/TD) | ≥ 140 MPa / ≥ 130 MPa | ASTM D882 |

| Elongation at Break | ≥ 80% (both directions) | ASTM D882 |

| Haze | ≤ 3.5% | ASTM D1003 |

| Water Vapor Transmission Rate | ≤ 2.0 g/m²·24h | ASTM E96 |

| Shrinkage (150℃, 30min) | ≤ 2.0% | ASTM D1204 |

| Surface Treatment | Corona treated or primer coated | Internal Standard |

PET FILM Application Fields:

Medical Device Packaging

Diagnostic test kits

Syringe blister trays

IV catheter pouches

Pharmaceutical Laminate Base

PET/PVDC film structures

PET/Aluminum foil for high-barrier pouches

PET/PE for recyclable blister packs

Custom Printed Packaging

High-resolution rotogravure or flexo printing

Suitable for branding and compliance labeling

Packaging & Supply Options

Formats: Roll stock or flat sheets

Width: 300mm – 1250mm (customizable)

Core Sizes: 73mm plastic cores

Colors: Transparent (standard), white, light blue (optional)

Coating Options: PVDC, PE, or Heat-seal layer on request

Sterilization Compatibility: EO, Gamma, Steam

FAQs – PET Film

Q1: Is your PET film suitable for direct contact with drugs?

A: Yes. All films are produced from FDA-compliant, pharma-grade PET resins and meet USP <661> extractables standards.

Q2: Can PET film be laminated with aluminum foil or PVDC?

A: Absolutely. We offer both PET/PVDC and PET/AL structures with high adhesion and superior barrier performance.

Q3: What’s the advantage of PET over PVC for pharma packaging?

A: PET provides higher mechanical strength, excellent recyclability, and better temperature stability without using chlorine-based materials.

Q4: Do you offer antistatic or matte finishes?

A: Yes. Antistatic treatment, matte surface, and printable coatings are available on request for volumes >2 tons.

Why Choose HealthPlast PET Film?

Produced in Class 100,000 Cleanroom for medical packaging

19+ years experience in pharmaceutical film extrusion and lamination

Available with PVDC/PE/AL foil composite structures

Custom slitting and express global shipping within 7 days

ISO 9001 & CE Certified / USP, EP, and JP Compliant